Overview

This cracker mill is a very important and very efficient machine in waste tyre recycling plant. It converts rubber chips from waste tyres or any waste rubber products to different size of rubber crumbs which can be used as the feedstock of continuous type waste tyre pyrolysis plant, rubber mulch for garden decoration, rubber granules for filling material of artificial turf, crumb rubber for playground paving & sports ground paving, rubber powder for reclaim rubber production, and rubber powder for modified asphalt for high grade express way paving.

This cracker mill machine can recycle the waste tyres into below products

Rubber Mulch

It can be used as TDF or the feedstock of continous Type waste tyre pyrolysis plant

Rubber Granules

It can be used as filling material of artifical turf, sports ground & play ground paving etc

Crumb Rubber

It can be used for making rubber tile, modified asphalt, moulded rubber products etc

Shredded Wires

It is very clean and can be sold at much higher value than the wires made by rasper

Reference Pictures from Customer Site

Our clients play a crucial role in our ongoing success, and it is with great satisfaction that we offer customized and effective solutions for their tire recycling needs. Below, we highlight some of the successful projects we have undertaken in collaboration with our esteemed clients:

- Pneumatic Conveyor for Tire Recycling: We implemented a pneumatic conveyor system for a client in Yangzhou, providing efficiency in handling recycled tires.

- TBR Tire Recycling Line: We developed a complete TBR tire recycling line for a client in Jiangsu, ensuring the production of high-quality recycled rubber.

- Magnetic Separator for Tire Recycling Plant: We installed a magnetic separator in a tire recycling plant, allowing for effective removal of impurities from the recycled material.

- Cracker Mill Plant for Rubber Powder Production: To meet the needs of a client in Jiangsu, we provided cracker mill plants that resulted in the production of high-standard rubber powder.

- Tire Recycling Lines: We successfully implemented eight complete tire recycling lines for a client in Jiangyin, significantly contributing to the production of recycled rubber.

- Efficient Wire Separator for Tire Recycling: For a client in Suzhou, we provided a highly efficient wire separator, ensuring seamless production of fine rubber powder.

- Steel Radial Tire Recycling Machine: We installed two steel radial tire recycling lines for a client in Taizhou, enabling the production of high-quality recycled rubber.

These are just a few examples of the successful projects we have undertaken in close collaboration with our valuable clients. We consistently demonstrate our ability to provide high-quality tire recycling solutions, meeting each client's specific demands with professionalism and excellence.

TBR Tyre Recycling Line for our Yangzhou Customer to Make Reclaim Rubber

Cracker Mill Plants for our Jiangsu Customer to make minus 30 mesh rubber powder Moreover, it will be very easy for maintenance by alloy welding in situ when the roll surface is worn, so, the roll has endless life.

Eight (8) Nos of Waste Tyre Recycling Line for our Jiangyin Customer to Make Reclaim Rubber

High Efficiency Waste Tire Recycling Machine for Suzhou Customer to Make Fine Rubber Powder

Two (2) Nos of Waste Tire Recycling Line for our Taizhou Customer to Make Reclaim Rubber

One (1) No of Waste Tyre Recycling Line for our Jinjiang Customer to Make Fine Rubber Powder

Four (4) Nos of Waste Tyre Recycling Plant for our Wuzhou Customer to Make Rubber Mulch for Tyre Pyrolysis

Four (4) Nos of Waste Tire Recycling Plant for our Gaoming Customer to Make Rubber Powder for Modified Aspahlt.

Eight (8) Nos of Waste Tire Recycling Plant for our Guangzhou Customer to Make Rubber Powder for Modified Aspahlt

Four (4) Nos of Waste Tyre Recycling Machines for our Yongzhou Customer to Make Rubber Mulch for Tyre Pyrolysis

Fully automatic Waste Tyre Recycling Plant for our Huizhou Customer to Make Rubber Powder for Pyrolysis

Eight (8) Nos of Waste Tyre Recycling Plant for our Qianyuan Customer to Make Rubber Powder for Modified Asphalt

Fully automatic Waste Tyre Recycling Plant for our Inner Mongonia Customer to Make Rubber Powder for Modified Asphalt

Eight (8) Nos of Waste Tyre Recycling Plant for our Cangzhou Customer to Make Rubber Powder for Reclaim Rubber

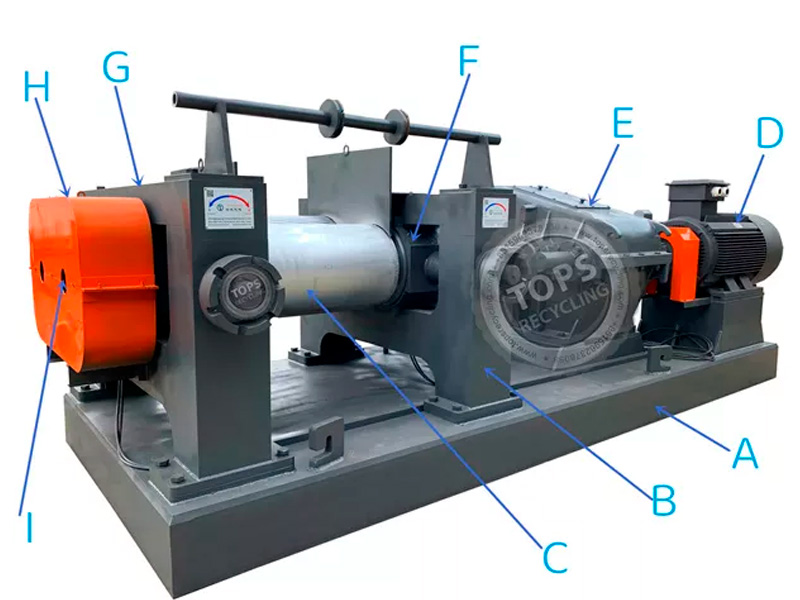

- A. Machine Base

- B. Roll Pillars

- C. Rolls

- D. Electrical Motors

- E. Bearing Sets

- F. Pillar Caps

- G. Speed Ratio Gears

- H. Water Cooling System

Specialty / Advantage of our cracker mill machine

①. High capacity rubber grinding mill

The machine frame, roll pillars, pillar caps, & bearing housing are made of C45 (or S45C by JIS, or 1045 by ASTM) steel for higher strength and we provide guarantee for the whole life of the machines.

②. Durable cracker mill rolls for sale

The rolls are made of C45 cast steel & its surface with overlay of alloy welding which achieve the hardness of above 60HRC. Moreover, it will be very easy for maintenance by alloy welding in situ when the roll surface is worn, so, the roll has endless life.

③. High Strength Cracker Mill Rolls

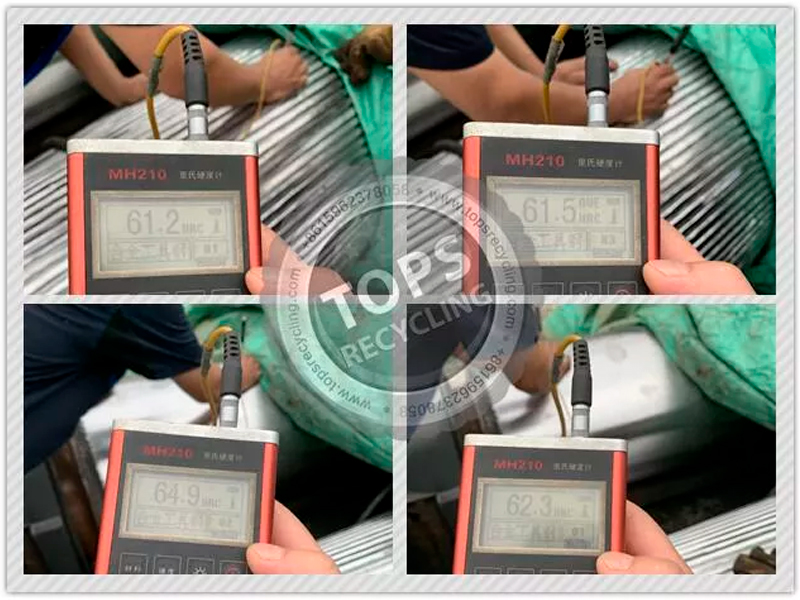

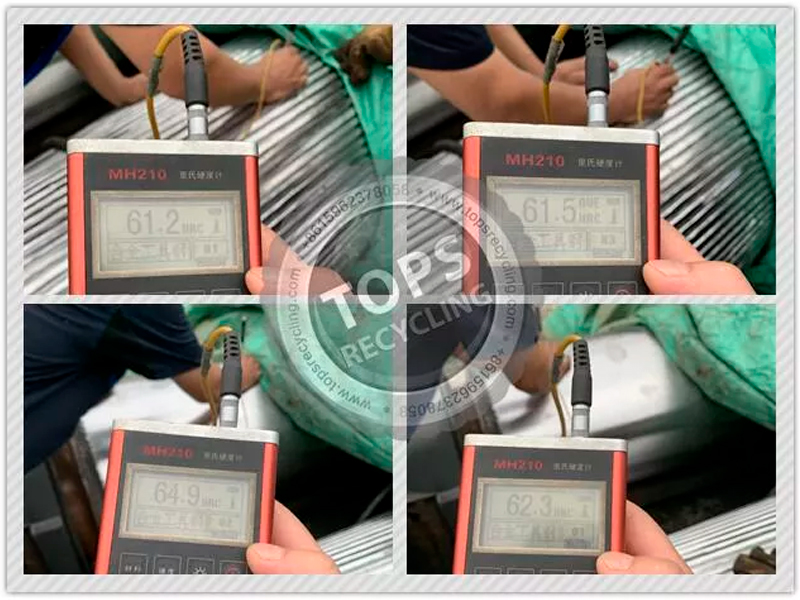

Hardness checking of the cracker mill rolls. It's average hardness is above 60 HRC. To compare with the cast iron roll, this one has much longer life, and it is easier for maintenance by alloy welding and simple grinding in situ.

④. Water Cooling System of Waste Tyre Recycling Machine

The machine is equipped with good water cooling to assure the temperature of end rubber crumb at minus 45℃. The surface temperature of groove roll @ minus 100℃. The surface temperature of plain roll @ minus 85℃.

①. High capacity rubber grinding mill

The machine frame, roll pillars, pillar caps, & bearing housing are made of C45 (or S45C by JIS, or 1045 by ASTM) steel for higher strength and we provide guarantee for the whole life of the machines.

②. Durable cracker mill rolls for sale

The rolls are made of C45 cast steel & its surface with overlay of alloy welding which achieve the hardness of above 60HRC. Moreover, it will be very easy for maintenance by alloy welding in situ when the roll surface is worn, so, the roll has endless life.

③. High Strength Cracker Mill Rolls

Hardness checking of the cracker mill rolls. It's average hardness is above 60 HRC. To compare with the cast iron roll, this one has much longer life, and it is easier for maintenance by alloy welding and simple grinding in situ.

④. Water Cooling System of Waste Tyre Recycling Machine

The machine is equipped with good water cooling to assure the temperature of end rubber crumb at minus 45℃. The surface temperature of groove roll @ minus 100℃. The surface temperature of plain roll @ minus 85℃.

Advantages of Automatic Waste Tyre Cutting Machine

- This machine could be customized for any machine components & outputs

- This machine can be used for recycling of whole tyres of large variety such as Truck/Bus Radial/Nylon, Passenger car, SUV, OTR, and others

- End products – granules of different sizes to fine powder up to 40 mesh size

- Crumb rubber production rate from one line to as high as 1500 kg per hour

- Extremely low energy consumption per ton of powder

- Endless life of rolls with ease of rebuilding working surface in situ without dismounting of rolls from mill with high surface hardness (above 60HRC)

- High purity of shredded wire, rubber powder, bead wire & all other products/by-products

- User and Maintenance friendly

- High performance and reliable major parts such as Gear Box, Motors, Bearings, All electrical etc.

- High sieving efficiency and trouble-free reciprocating mechanism

- Less manpower required for wheel prioress per ton output

- Flexibility for customized automation from feeding of feedstock to weighing/packing of finished output

- Extended Warranty period

- Life time technical support for operation and maintenance

- Guaranteed production rate and established during commissioning trials by our team at customer site

Technical data of this automatic waste tire cutting machine

| No. |

Items |

Machine Model |

TXKP-560 (220V) |

TXKP-610 (220V) |

TXKP-710 (220V) |

TXKP-810 (220V) |

| 1 |

Installed Motor Power |

Rubber Powder Line |

160 kW |

200 kW |

250 kW |

280 kW |

| 2 |

Cracker Mill |

|

160 kW |

200 kW |

250 kW |

280 kW |

| 3 |

Auxiliary Machines |

|

27.5 kW |

27.5 kW |

36.5 kW |

49.5 kW |

| 4 |

Rubber Mulch Line |

Cracker Mill |

160 kW |

200 kW |

250 kW |

280 kW |

| 5 |

Auxiliary Machines |

|

23 kW |

23 kW |

30.7 kW |

42.5 kW |

Detailed Technical Data

| No. |

Details |

Machine Model |

TXKP-560 |

TXKP-610 |

TXKP-710 |

TXKP-810 |

| 1 |

Groove roll (φ×L in mm) |

|

560×800 mm |

610×1000 mm |

710×1100 mm |

810×1200 mm |

| 2 |

Plain roll (φ×L in mm) |

|

510×800 mm |

510×1000 mm |

610×1100 mm |

710×1200 mm |

| 3 |

Gear Box Torque |

|

73 Torque |

73 Torque |

89 Torque |

105 Torque |

| 4 |

Production Capacity (@ 22mesh size) |

Kg/Hr |

600~800 |

800~1200 |

1200~1500 |

1500~2000 |

| 5 |

Main Motor Power (kW) |

|

160 kW |

200 kW |

250 kW |

280 kW |

| 6 |

Rolls Gap Range (mm) |

|

0.1~20 mm |

0.1~20 mm |

0.1~20 mm |

0.1~20 mm |

| 7 |

Way of Brake |

|

Motor Emergency Stop & power source reversal connections braking |

Motor Emergency Stop & power source reversal connections braking |

Motor Emergency Stop & power source reversal connections braking |

Motor Emergency Stop & power source reversal connections braking |

| 8 |

Type of Bearing |

|

Thrust bearing plus mill bearing |

Thrust bearing plus mill bearing |

Thrust bearing plus mill bearing |

Thrust bearing plus mill bearing |

| 9 |

Type of Lubrication |

|

Grease |

Grease |

Grease |

Grease |

| 10 |

Way of Cooling |

|

Water Cooling |

Water Cooling |

Water Cooling |

Water Cooling |

| 11 |

Material of Machine Frame, Roll pillars, Rolls, Bearing housing etc |

|

Cast Steel |

Cast Steel |

Cast Steel |

Cast Steel |

| 12 |

Cracker Mill Machine Weight |

Tons |

20 |

22 |

30 |

45 |

| 13 |

Machine Size (L×W×H in mm) |

|

5400×2000×1400 |

5400×2000×1400 |

6200×2260×1700 |

6400×2700×2400 |